- Home

- Product Center

- Conveyor Belts

- Balanced Mesh Conveyor Belt

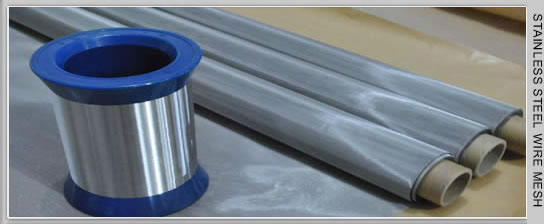

Balanced Woven Stainless Steel Mesh Belt SS 304 for Conveyor Belt Furnaces, Transfer System and Architectural Uses

Balanced Weave Wire Mesh Conveyor Belt in SS 304 can supplied in 3 types according to woven patterns: Standard Balanced Spiral Woven Mesh, Double Balanced Spiral Woven Conveyor Belts and Compound Balanced Woven Mesh.

Products Overview

Range of mesh conveyor belts from 150mm to 1500mm wide and 10m to 100m long.

Material: 304SS.

Optional: 80/20 (Nichrome), Inconel 601

Mesh types:

Standard Balanced Woven Conveyor Belt

Double Balanced Spiral Woven Conveyor Belts

Compound Balanced Mesh.

Belt Edge Options for Balanced Spiral Woven Conveyor Belts

Welded Edge

Welded edge is common and economical edge finish by welding together both the coil and crimped wires, simple operation and less cost, without cut wire ends. Balanced mesh conveyor belt with weld edge enjoy following features:

Economical: Common welded edge design

Durable Construction: Welding of coil and crimped wires

Cost-Effective: Simple operation, no additional expenses

Safe Handling: No exposed or cut wire ends

Laddered Edge

Ladder edge is less used compared with welded edge, it is often used as an option where welds are not desirable for the application and in such applications where welding facilities are not available.

Laddered edge balanced mesh belt enjoy following features:

Smooth Belt Edge for Enhanced Flexibility

High-Efficiency in High-Temperature Applications

Reduced Fracture Risk with Laddered Edge Design

Suitable for Meshes with Large Crimp Wire Pitch

Hook Edge

Hook edge is used as options for weld edges where welds are not desirable for the application, and in applications where welding facilities are not available.

Chain Edge

Chain edge conveyor belt operates through side chains driving the wire meshes, utilizing cross rods inserted through the mesh coils and connected to chains along the mesh edges.

Balanced Mesh Belts for Conveyor Belt Furnaces, Transfer System and Architectural Uses

Balanced Weave Wire Mesh Belts - SS 304 - with Side Chains

Woven wire mesh details:

Balanced weave 3.1X3.6X1.25X0.9;

Edge type: welded;

Woven wire mesh with spiral at 50.8MM centers for Ø3.66MM S/S cross rods;

Belt overall width: 1210MM maximum (+0/-2MM), length 18 meters.

Mesh and rod materials: stainless steel T304.

Chain and Chain Connecting to the Rods:

Chain centers: 1191 norminal

C2042 connecting links every 48 pitches facing inwards;

Side chains C2042 on both sides fitted to cross rods.

Cross rods replace chain pins.

Cross rod ends to be welded to washers on outside of chain links.

Welds heliarc or equivalent. Welds large and sound.

Cross rods must be free to rotate.

No clearance between belt mesh and side chains.

Chain Material: Carbon steel.

T304 Stainless Steel Balanced Belts - for Maximum Working Temperature 1,400 °f

T304 stainless steel mesh belt

Width 72"

Maximum opening of .12 in. for a maximum working tension of 2,714.4 lb/ft. with a belt weight of 5,275 lb/ft.

Material:

with the % of the following elements manganese 1.00% max carbon .12% max silicon 1.00% max chromium 14.00 to 18.00% for a maximum working temperature of 1,400 °f, with a steel wear factor of .982%, welded side areas, assorted each band in 4 sections with rolls marked for continuity in the installation.

Standard Balanced Mesh Belting 18 inch Wide, Chained Drive

Belting:

Standard balanced

Material: Stainless steel

Belt size: 18” wide x 60’ long

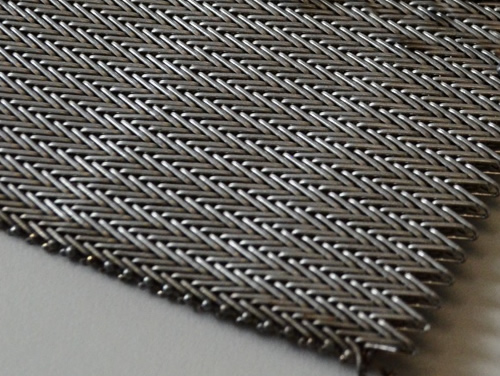

Balanced Mesh Belt Compound Weave - SS 304 Chevron Mesh for Furnace

Compound Balanced Weave Mesh Belt, also known as Chevron Wire Conveyor Belt, V Mesh Conveyor Belt.

Balanced Mesh Belt Compound Weave Chevron Structure is a dense mesh metal conveyor belt ideally used for small item transfering, also used for architectural meshes.

Features:

Uniform chevron structure, spirals interlaced;

Dense mesh;

No cross rods;

Flat surface;

Open area 85% min. suitable for air flow, cooling, also shading for building wall cladding;

Mininum contact with belt;

Available in multi color and treatments.

Metal materials options: Spring wire, carbon steel wire, stainless steel wire. Steel wire available in bronze, gold, silver and color for decorative uses.

Tips for Choosing Balanced Mesh or Compound Balanced Mesh for Your Conveyor System

Capable of withstanding high temperatures without losing integrity, Stainless Steel 304 Balanced Weave Wire Mesh Conveyor Belt is a reliable, efficient, and versatile choice for a wide array of industrial applications.

Considering mainly following three points when choosing:

1, Balanced Weave Wire Mesh Conveyor Belt stands out for its robustness and exceptional corrosion resistance, ideal for use in environments prone to moisture and chemical exposure, such as in food processing, pharmaceuticals, and chemical industries.

2, The balanced weave design, featuring alternating single or double spirals connected by straight or crimp rods, ensures a flat and stable surface, suitable for a broad spectrum of application.

3, This design not only provides the necessary flexibility for handling different load sizes but also contributes to the belt's overall strength, making it capable of conveying both light and heavy loads efficiently.

Compound Balanced Weave Mesh Conveyor Belt Stainless Steel 304, offers exceptional durability and corrosion resistance, ideal for demanding industrial environments. Considering mainly following 3 points when choosing:

1, The tightly woven structure of V mesh provides a stable, flat surface, perfect for transporting delicate or small items efficiently.

2,

The chevron robust design ensures high strength and stability, supporting heavier loads with ease.

3, The V mesh provides a decorative effect, suitable for architectural cladding.

Stainless Steel Wire Mesh Products

- Wire Mesh Pleated Candle Filter

- Stainless Steel Mesh Extruder Screen

- Stainless Steel Filter Disc

- 904 L Stainless Steel Wire Mesh

- 304 and 316 Stainless Steel Wedge Wire

- Stainless Steel Mesh, Knitted

- Micron Stainless Steel Wire Mesh

- Stainless Steel Mesh Sheet

- Stainless Steel Perforated Metal

- Stainless Steel Architectural Mesh

- 304 and 316 Stainless Steel Screen

- Stainless Steel Wire Mesh Sifting Screen

- Powder Coated Stainless Steel Screen Mesh

- Stainless steel decorative mesh for large venues

- Stainless Steel Bolting Cloth

- Stainless Steel Woven Mesh Cloth Test Sieves

- Stainless Steel Wire Cloth,Reverse Dutch Weave

- Wire Mesh Filter Cloth

- Square Opening Wire Mesh

- Stainless Steel Welded Wire Mesh

- Stainless Steel Crimped Wire Mesh

- Belt Mesh

- Stainless Steel Insect Screen

- Stainless Steel Mesh, Welded, Woven, 304 Grade

- Stainless Steel Hexagonal Chicken Wire

- Hexagonal Mesh

- Bullet Proof Woven Wire Mesh

- Stainless Steel Woven Wire Mesh

- Stainless Steel Woven Filtering Mesh

- Stainless Steel Woven Mesh Discs

- Woven Wire Mesh for Testing Sieves

- High Tensile Woven Wire Screen