- Home

- Product Center

- Conveyor Belts

- Oven Belt

Roller Chain Driven Woven Belt for Continuous Oven Conveyors

Oven Belts are integral components in various baking and drying processes, specifically designed to withstand high temperatures and continuous operations. These belts are essential for efficient heat transfer and product movement in industrial baking, drying, and cooling applications.

Products Overview

Major Materials:

Stainless steel for its high strength, heat, and corrosion resistance, making it ideal for food processing;

Carbon steel is more economical but less corrosion-resistant;

Nickel alloys are used for extremely high-temperature applications due to superior thermal and corrosion resistance.

Mesh Types:

Balanced mesh;

Compound weave;

Chain link weave.

Edge Types: The welded edge ensures a smooth finish to reduce snags or tears; the chain edge increases strength and maintains belt shape and alignment; the folded edge is perfect for preventing mesh unraveling while adding additional strength.

Uses

Baking Industry: For bread, pastries, pizzas, and other baked goods.

Drying Processes: Used in the dehydration of fruits, vegetables, and herbs.

Cooling Lines: Essential in cooling down products post-baking or cooking.

Chemical Processing: In the handling and processing of chemicals requiring high-temperature resistance.

Oven Belts - Types, Specifications, Case Study

We manufacture and supply Oven Belts with a variety of mesh styles, stainless steel grades sheets, edges.

Choose the right Oven Belts - Roller Chain Woven Wire Mesh Conveyor Belt

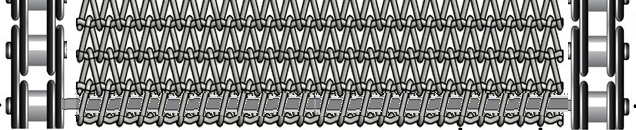

Made from woven wire mesh driven by a roller chain mechanism, this type of belt is commonly used in industrial applications that require both the durability and flexibility of a woven mesh combined with the reliable drive mechanism provided by a roller chain.

This Conveyor Belt is commonly used as an oven belt in various industrial applications, for three reasons:

The design combines the resilience and heat resistance of woven wire mesh with the strength and stability of a roller chain drive, makes it particularly suitable for high-temperature environments such as those found in baking, drying, and curing ovens;

The mesh belt allows for efficient heat transfer and uniform cooking or processing;

The unique structure facilitates even heat distribution and efficient product transfer, ideal for various industrial oven operations.

Woven Belt Roller Chain Driven - For Oven Conveyors

Woven mesh belt with roller chain made of stainless steel heavy weave mesh

Purpose: Specialized conveyor component designed specifically for oven applications, particularly suitable for high-temperature baking and drying processes.

Drawing refering to below:

Oven conveyor construction with a slider bed of metal bars that provides for ovens convection oven reaches 1200®C

Belt for Paint Oven

Fabric mesh belts for paint oven.

Stainless Steel Belt for high heat resistant arounf 500 degrees F

Size 85” x 56’ finished

Size option 85” x 28’ finished

For USA customers

Stainless Conveyor Belt - Furnace Belt

Size: 11 Meters x 450 mm wide

Material: Stainless steel, carbon steel at request

Maximum Temperature 620c

Transfer Band for Oven Input for Wood Panel

Metal band size 3300 mm wide x 10380 mm long

With pin to close and has a silicone cover

Conveyor Belt for Furnace - Exported to USA

Size: 25 IN. wide balanced mesh designation B-42-36-18-20 WD-80-20CB

Rods 80-20CB-18

Spirals 80-20CB-20

With welded selvages

Purpose: For USA customers, use at Electronic Contract Manufacturer on oven/furnace to bake electronic parts

Solid Band Nickle Chrome Stainless Steel Furnace Conveyor Belts - Exported to UK

Work condition: To withstand a temperature of 880 C produced by a gas fired furnace

Purpose: Heat treats Circlips of various sizes.

Project: UK customer used a wire meshed belts, replace it with a continuous solid band type belt or a segmented solid type.

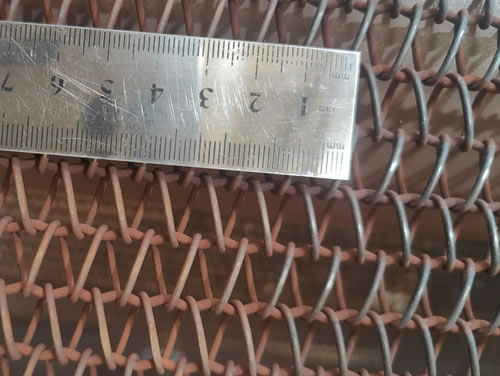

Oven Belt - Wire Mash Conveyor Belt for Isreal Project

Wire mesh conveyor belt

Long 100 m x Width 1400 mm

Mesh wire size 3 mm

Material steel

Durable 304 Stainless Steel Balanced Weave Conveyor Belt for Precision Baking and Drying Ovens

Replacing a carbon steel oven belt with a stainless steel 304 oven belt in a project for following reasons:

Doesn't Rust Easily: Stainless steel 304 is much better at resisting rust compared to carbon steel. This is really important in places where there's a lot of heat and moisture, like in ovens.

Handles Heat Well: Stainless steel 304 can take higher temperatures without getting damaged. This makes it great for ovens that need to be really hot.

Safe for Food: Stainless steel 304 is safer for cooking and baking because it doesn’t affect the food. It's also easier to clean, which keeps food safe from germs.

Lasts Longer: Even though it might cost more at first, stainless steel 304 lasts longer than carbon steel. This means you don't have to replace it as often, saving money in the long run.

Gentle on Food: Stainless steel 304 belts are usually smoother, so they're better for moving delicate food items without damaging them.

Steel conveyor belt Isreal customer needs to replace:

Choosing a stainless steel 304 oven belt ensures that the project will have a belt that lasts longer, works better in heat, is safer for food, and needs less replacing.

Stainless Steel Wire Mesh Products

- Wire Mesh Pleated Candle Filter

- Stainless Steel Mesh Extruder Screen

- Stainless Steel Filter Disc

- 904 L Stainless Steel Wire Mesh

- 304 and 316 Stainless Steel Wedge Wire

- Stainless Steel Mesh, Knitted

- Micron Stainless Steel Wire Mesh

- Stainless Steel Mesh Sheet

- Stainless Steel Perforated Metal

- Stainless Steel Architectural Mesh

- 304 and 316 Stainless Steel Screen

- Stainless Steel Wire Mesh Sifting Screen

- Powder Coated Stainless Steel Screen Mesh

- Stainless steel decorative mesh for large venues

- Stainless Steel Bolting Cloth

- Stainless Steel Woven Mesh Cloth Test Sieves

- Stainless Steel Wire Cloth,Reverse Dutch Weave

- Wire Mesh Filter Cloth

- Square Opening Wire Mesh

- Stainless Steel Welded Wire Mesh

- Stainless Steel Crimped Wire Mesh

- Belt Mesh

- Stainless Steel Insect Screen

- Stainless Steel Mesh, Welded, Woven, 304 Grade

- Stainless Steel Hexagonal Chicken Wire

- Hexagonal Mesh

- Bullet Proof Woven Wire Mesh

- Stainless Steel Woven Wire Mesh

- Stainless Steel Woven Filtering Mesh

- Stainless Steel Woven Mesh Discs

- Woven Wire Mesh for Testing Sieves

- High Tensile Woven Wire Screen