- Home

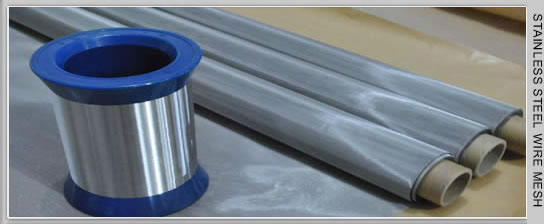

- Product Center SS 321 Wire Mesh

High-Temperature Resistant 321 Stainless Steel Wire Mesh ASME SA240

SS 321 wire mesh is made from stainless steel grade 321, a titanium-stabilized alloy in the 300-series family. SS 321 mesh combines the corrosion resistance of 304 stainless steel with superior performance at elevated temperatures up to ~850 °C.

Material Standard

SS 321 wire mesh is manufactured from stainless steel grade 321, meeting standards ASTM A240, ASTM A479 and ASME SA240.

Features

SS 321 mesh offers excellent oxidation resistance up to ~850 °C, high creep strength, and good toughness under thermal cycling. Compared with 304 stainless steel, 321 grade stainless steel mesh maintains superior stability at elevated temperatures, suitable for filtration and structural screening.

Applications

SS 321 wire mesh is widely used in petrochemical, aerospace, heat-treatment, filtration and drying equipment. With good mechanical strength, dimensional stability and resistance to scaling, SS 321 wire mesh is a reliable choice for demanding industrial filtration and screening applications.

321 Stainless Steel Wire Mesh - ASME SA240 -4 Mesh

High-Temperature Resistant Wire Netting

Mesh Count: 4 mesh (4 openings per linear inch)

Wire Diameter: 1.2 mm

Aperture Size: ˜ 5.15 mm (calculated)

Material: Stainless Steel 321 (ASME SA240)

Form: Rolls, 1200 mm width × 10 m length

Standard Compliance: ASME SA240 plate grade, commonly supplied as drawn wire for mesh

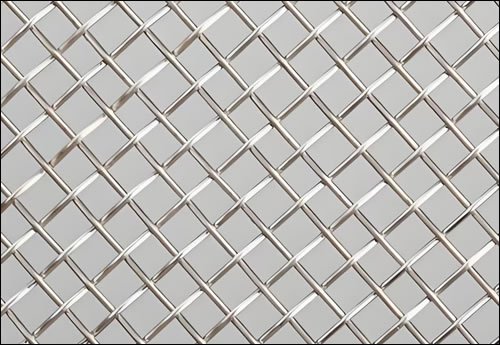

321 Stainless Steel Wire Mesh - ASME SA240 - 20 Mesh

20 Mesh Stainless Steel Cloth

Mesh Count: 20 mesh (20 openings per linear inch)

Wire Diameter: 0.40 mm

Aperture Size: ˜ 0.87 mm

Material: Stainless Steel 321 (ASME SA240)

Form: Rolls, 1200 mm width × 10 m length

Standard Compliance: ASME SA240

Selection Tips of SS Mesh Materials

Choose 304 SS for standard corrosion resistance at lower cost.

Choose 316 SS where chloride or acid resistance is critical.

Choose 321 SS for high-temperature filtration and thermal cycling applications.

Comparison of SS 304 vs. SS 316 vs. SS 321 wire mesh for quick buyer reference:

Comparison of SS 304, SS 316, and SS 321 Wire Mesh

| Grade | Standards | Main Alloying Elements | Key Features | Typical Applications |

|---|---|---|---|---|

| SS 304 Wire Mesh | ASTM A240, ASTM A580, ASME SA240 | 18% Cr, 8% Ni | General-purpose stainless steel with good corrosion resistance, weldability, and strength at moderate temperatures | Food processing screens, architectural mesh, sieves for powders and liquids, general industrial filtration |

| SS 316 Wire Mesh | ASTM A240, ASTM A580, ASME SA240 | 18% Cr, 10% Ni, 2% Mo | Superior resistance to chlorides and acids, better pitting and crevice corrosion resistance than 304 | Marine mesh, chemical filtration, pharmaceutical filters, medical sieves, saltwater environments |

| SS 321 Wire Mesh | ASTM A240, ASTM A479, ASME SA240 | 17% Cr, 9% Ni, Ti stabilized | Excellent high-temperature resistance, oxidation resistance up to ~850 °C, resists intergranular corrosion during thermal cycling | Aerospace exhaust filters, refinery screens, dryer meshes, petrochemical equipment, heat-treatment baskets and trays |

Stainless Steel Wire Mesh Products

- Ring Shaped Filter Disc

- Mesh Discs Twill Weave

- Plain Steel Mesh Filter Discs

- Wire Mesh Pleated Candle Filter

- Stainless Steel Mesh Extruder Screen

- Stainless Steel Filter Disc

- 904 L Stainless Steel Wire Mesh

- 304 and 316 Stainless Steel Wedge Wire

- Stainless Steel Mesh, Knitted

- Micron Stainless Steel Wire Mesh

- Stainless Steel Mesh Sheet

- Stainless Steel Perforated Metal

- Stainless Steel Architectural Mesh

- 304 and 316 Stainless Steel Screen

- Stainless Steel Wire Mesh Sifting Screen

- Powder Coated Stainless Steel Screen Mesh

- Stainless steel decorative mesh for large venues

- Stainless Steel Bolting Cloth

- Stainless Steel Woven Mesh Cloth Test Sieves

- Stainless Steel Wire Cloth,Reverse Dutch Weave

- Wire Mesh Filter Cloth

- Square Opening Wire Mesh

- Stainless Steel Welded Wire Mesh

- Stainless Steel Crimped Wire Mesh

- Belt Mesh

- Stainless Steel Insect Screen

- Stainless Steel Mesh, Welded, Woven, 304 Grade

- Stainless Steel Hexagonal Chicken Wire

- Hexagonal Mesh

- Bullet Proof Woven Wire Mesh

- Stainless Steel Woven Wire Mesh

- Stainless Steel Woven Filtering Mesh

- Stainless Steel Woven Mesh Discs

- Woven Wire Mesh for Testing Sieves

- High Tensile Woven Wire Screen